Peripherals#

%connect serial:///dev/ttyAMA1

Connected to robot-stm32 @ serial:///dev/ttyAMA1

Configuration#

/boot/config.txt: add

[pi4]

dtoverlay=uart3

dtoverlay=uart4

enable_uart=0

Balena: configure dtoverlay from the dashboard.

Overlay enable_uart=0 disables the console UART on pins 8, 10. No need to disable if pins are not connected (but then there is no way this can work with a Pi 3, probably ok).

UART Assignments (Pi 4):

Pi 4 STM32

/dev/ttyAMA1 uart3 uart6 (REPL)

/dev/ttyAMA2 uart4 uart3 (dfu, robot comm)

GPIO Pins:

BOOT0 = 13 (GPIO27)

SHUT_DN = 33 (GPIO13) shutdown button input (active low)

nRST = 40 (GPIO21)

AUX = 36 (GPIO16) stm32: AUX

stm32: PWR_EN: pull low to cut main (5V) power supply

stm32: V12_DIV: 12V input / 7.8

GPIO#

List of available GPIOs and their capabilities:

# pin alternate functions

from pyb import Pin

print("{:15} {:4} {}".format('board name', 'name', 'alternate functions'))

for p in sorted(dir(Pin.board)):

if '__' in p: continue

pin = Pin(p)

names = pin.names()

print("{:15} {:4} {}".format(names[1], names[0], pin.af_list()))

Show code cell output

board name name alternate functions

AIN1 C5 []

AIN2 C1 []

AUX B13 [Pin.AF1_TIM1, Pin.AF5_SPI2, Pin.AF7_USART3]

BATTERY_MONITOR A3 [Pin.AF1_TIM2, Pin.AF2_TIM5, Pin.AF3_TIM9, Pin.AF7_USART2]

BIN1 C3 [Pin.AF5_SPI2]

BIN2 A4 [Pin.AF5_SPI1, Pin.AF7_USART2]

BOOT1 B2 []

D8 C0 []

ENC_A1 A6 [Pin.AF1_TIM1, Pin.AF2_TIM3, Pin.AF3_TIM8, Pin.AF5_SPI1, Pin.AF9_TIM13]

ENC_A2 A7 [Pin.AF1_TIM1, Pin.AF2_TIM3, Pin.AF3_TIM8, Pin.AF5_SPI1, Pin.AF9_TIM14]

ENC_B1 B6 [Pin.AF2_TIM4, Pin.AF4_I2C1]

ENC_B2 B7 [Pin.AF2_TIM4, Pin.AF4_I2C1]

FLASH_CS A15 [Pin.AF1_TIM2, Pin.AF1_TIM2, Pin.AF5_SPI1]

FLASH_MISO B4 [Pin.AF2_TIM3, Pin.AF5_SPI1]

FLASH_MOSI B5 [Pin.AF2_TIM3, Pin.AF5_SPI1]

FLASH_SCK B3 [Pin.AF1_TIM2, Pin.AF5_SPI1]

NC_A0 A0 [Pin.AF1_TIM2, Pin.AF1_TIM2, Pin.AF2_TIM5, Pin.AF3_TIM8, Pin.AF7_USART2]

NC_A1 A1 [Pin.AF1_TIM2, Pin.AF2_TIM5, Pin.AF7_USART2]

NC_A2 A2 [Pin.AF1_TIM2, Pin.AF2_TIM5, Pin.AF3_TIM9, Pin.AF7_USART2]

D8 C0 []

NSTBY C2 [Pin.AF5_SPI2]

PWM_A B15 [Pin.AF1_TIM1, Pin.AF3_TIM8, Pin.AF5_SPI2, Pin.AF9_TIM12]

PWM_B A5 [Pin.AF1_TIM2, Pin.AF1_TIM2, Pin.AF3_TIM8, Pin.AF5_SPI1]

PWR_EN B14 [Pin.AF1_TIM1, Pin.AF3_TIM8, Pin.AF5_SPI2, Pin.AF7_USART3, Pin.AF9_TIM12]

RX B11 [Pin.AF1_TIM2, Pin.AF4_I2C2, Pin.AF7_USART3]

RX_AUX C7 [Pin.AF2_TIM3, Pin.AF3_TIM8, Pin.AF8_USART6]

SCL B8 [Pin.AF2_TIM4, Pin.AF3_TIM10, Pin.AF4_I2C1, Pin.AF9_CAN1]

SDA B9 [Pin.AF2_TIM4, Pin.AF3_TIM11, Pin.AF4_I2C1, Pin.AF5_SPI2, Pin.AF9_CAN1]

SD_CK C12 [Pin.AF7_USART3]

SD_CMD D2 [Pin.AF2_TIM3]

SD_D0 C8 [Pin.AF2_TIM3, Pin.AF3_TIM8, Pin.AF8_USART6]

SD_D1 C9 [Pin.AF2_TIM3, Pin.AF3_TIM8]

SD_D2 C10 [Pin.AF7_USART3]

SD_D3 C11 [Pin.AF7_USART3]

SD_DETECT B12 [Pin.AF1_TIM1, Pin.AF5_SPI2, Pin.AF7_USART3]

SWCLK A14 []

SWDIO A13 []

TX B10 [Pin.AF1_TIM2, Pin.AF4_I2C2, Pin.AF5_SPI2, Pin.AF7_USART3]

TX_AUX C6 [Pin.AF2_TIM3, Pin.AF3_TIM8, Pin.AF8_USART6]

USB_DM A11 [Pin.AF1_TIM1, Pin.AF9_CAN1]

USB_DP A12 [Pin.AF1_TIM1, Pin.AF9_CAN1]

USB_ID A10 [Pin.AF1_TIM1]

USB_VBUS A9 [Pin.AF1_TIM1]

V12_DIV C4 []

Motor Controller#

I use HPCB micro gear motors with extended shaft (to mount the encoder magnet) and 210:1 gear ratio.

The motor controller comprises two H-bridges to control the speed and direction of the motors and magnetic encoders to capture the rotational speed.

H-bridges#

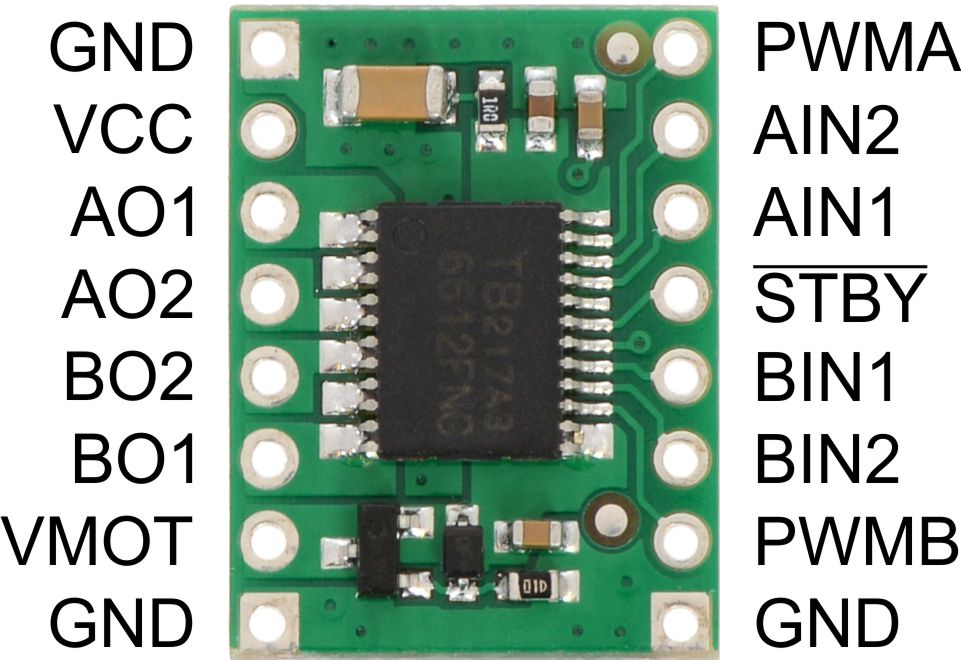

The figure below shows the TB6612 motor controller. It is wired to the STM32 as follows:

Channel A control: PWMA, AIN1, AIN2

Channel B control: PWMB, BIN1, BIN2

The xIN1 and xIN2 determine its state as follows:

Function |

IN1 |

IN2 |

Notes |

|---|---|---|---|

Forward |

L |

H |

|

Reverse |

H |

L |

|

Brake |

H |

H |

speed=0 has same effect |

Coast (Z) |

L |

L |

The TB6612 class maps the desired speed input to the appropriate control signals:

%cat /flash/lib/tb6612.py

Show code cell output

"""

TB6612 motor driver.

Example:

from pyb import Pin, Timer

from tb6612 import TB6612

import time

freq = 10_000

tim = Timer(8, freq=freq)

motor1 = TB6612(

tim.channel(3, Timer.PWM_INVERTED, pin=Pin('PWM_A')),

Pin('AIN1', mode=Pin.OUT_PP),

Pin('AIN2', mode=Pin.OUT_PP)

)

motor2 = TB6612(

tim.channel(1, Timer.PWM_INVERTED, pin=Pin('PWM_B')),

Pin('BIN1', mode=Pin.OUT_PP),

Pin('BIN2', mode=Pin.OUT_PP)

)

nstby = Pin('NSTBY', mode=Pin.OUT_PP)

nstby.value(1)

motor1.speed(30)

motor2.speed(-83)

time.sleep(5)

nstby.value(0)

"""

class TB6612:

def __init__(self, pwm, scale, in1, in2):

self.pwm = pwm

self.scale = scale

self.in1 = in1

self.in2 = in2

def speed(self, speed:float):

"""Set motor speed (duty cycle), range +/- 100."""

if speed < 0:

self.in1.value(0)

self.in2.value(1)

else:

self.in1.value(1)

self.in2.value(0)

speed *= self.scale

self.pwm.pulse_width(int(abs(speed)))

Example:

from tb6612 import TB6612

from pyb import Pin, Timer

# motor power control

nstby = Pin('NSTBY', mode=Pin.OUT_PP)

nstby.value(0)

# motors

pwm_timer = Timer(8, freq=10_000)

scale = (pwm_timer.period()+1)/100

motor1 = TB6612(

pwm_timer.channel(3, Timer.PWM_INVERTED, pin=Pin('PWM_A')),

scale,

Pin('AIN1', mode=Pin.OUT_PP),

Pin('AIN2', mode=Pin.OUT_PP)

)

motor2 = TB6612(

pwm_timer.channel(1, Timer.PWM_INVERTED, pin=Pin('PWM_B')),

scale,

Pin('BIN1', mode=Pin.OUT_PP),

Pin('BIN2', mode=Pin.OUT_PP)

)

Connected to robot-stm32 @ serial:///dev/ttyAMA1

Start motors: if everything is wired correctly, the motors will spin when running the code in next cell.

from time import sleep

# enable TB6612

nstby.value(1)

for speed in range(0, 101, 20):

# set desired speed (PWM duty cycle)

motor1.speed(speed)

motor2.speed(speed)

sleep(1)

motor1.speed(0)

motor2.speed(0)

nstby.value(0)

Encoder#

Just like a car, motor speed depends on load. Encoders can be used to measure the position (and, by taking the derivative, speed).

I’ve chosen magnetic encoders:

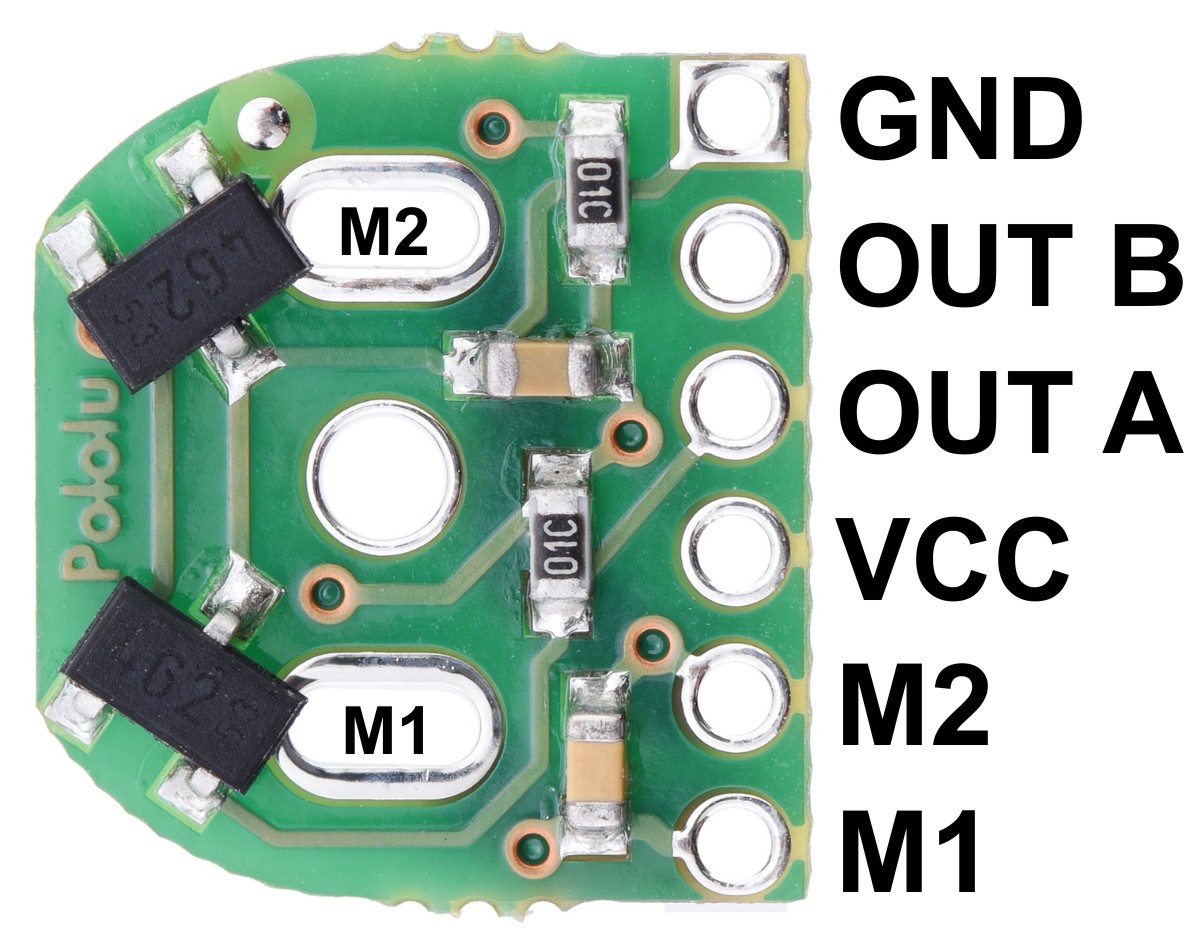

Fig. 26 Magnetic Encoder breakout boards.#

A wheel with several magnetic zones with with alternating magnetization mounted to the shaft to the motor passes two magnetic sensors (the black components on the board) to produce electrical pulses. The STM32 has built-in counters to tally up these pulses.

!cat code/stm32/lib/encoder16.py

Show code cell output

from pyb import Pin, Timer

"""

Encoder readout for STM32 16-bit timers. Corrects for counter over/under-flow.

"""

class Encoder16:

def __init__(self, timer_no, ch1_pin, ch2_pin, af):

pin_a = Pin(ch1_pin, Pin.AF_PP, pull=Pin.PULL_NONE, af=af)

pin_b = Pin(ch2_pin, Pin.AF_PP, pull=Pin.PULL_NONE, af=af)

timer = Timer(timer_no, prescaler=0, period=0xffff)

channel = timer.channel(1, Timer.ENC_AB)

self._timer = timer

self._sum = 0

self._cnt = timer.counter()

def count(self):

c = self._timer.counter()

if c-self._cnt > 0x8fff:

print("under")

self._sum -= 0x10000

if self._cnt-c > 0x8fff:

print("over")

self._sum += 0x10000

self._cnt = c

return self._sum + c

"""

Example:

enc = Encoder16(3, 'ENC_B1', 'ENC_B2', Pin.AF2_TIM3)

last = enc.count()

while True:

c = enc.count()

if abs(last-c) > 5:

last = c

print(f"{c:6d}")

"""

from encoder16 import Encoder16

from pyb import Pin

enc1 = Encoder16(4, 'ENC_A1', 'ENC_A2', Pin.AF2_TIM4)

enc2 = Encoder16(3, 'ENC_B1', 'ENC_B2', Pin.AF2_TIM3)

A complete example:

import time

# enable TB6612

nstby.value(1)

last1 = enc1.count()

last2 = enc2.count()

for duty in range(0, 101, 20):

motor1.speed(duty)

motor2.speed(duty)

time.sleep(0.5)

cnt1 = enc1.count()

cnt2 = enc2.count()

print(f"{duty:3d} cnt1={cnt1:6d} cnt2={cnt2:6d} speed1={cnt1-last1:6d} speed2={cnt2-last2:6d}")

last1 = cnt1

last2 = cnt2

nstby.value(0)

0 cnt1= 0 cnt2= 0 speed1= 0 speed2= 0

20 cnt1= 846 cnt2= 912 speed1= 846 speed2= 912

40 cnt1= 2959 cnt2= 3081 speed1= 2113 speed2= 2169

60 cnt1= 6282 cnt2= 6500 speed1= 3323 speed2= 3419

80 cnt1= 10688 cnt2= 11071 speed1= 4406 speed2= 4571

100 cnt1= 15835 cnt2= 16711 speed1= 5147 speed2= 5640

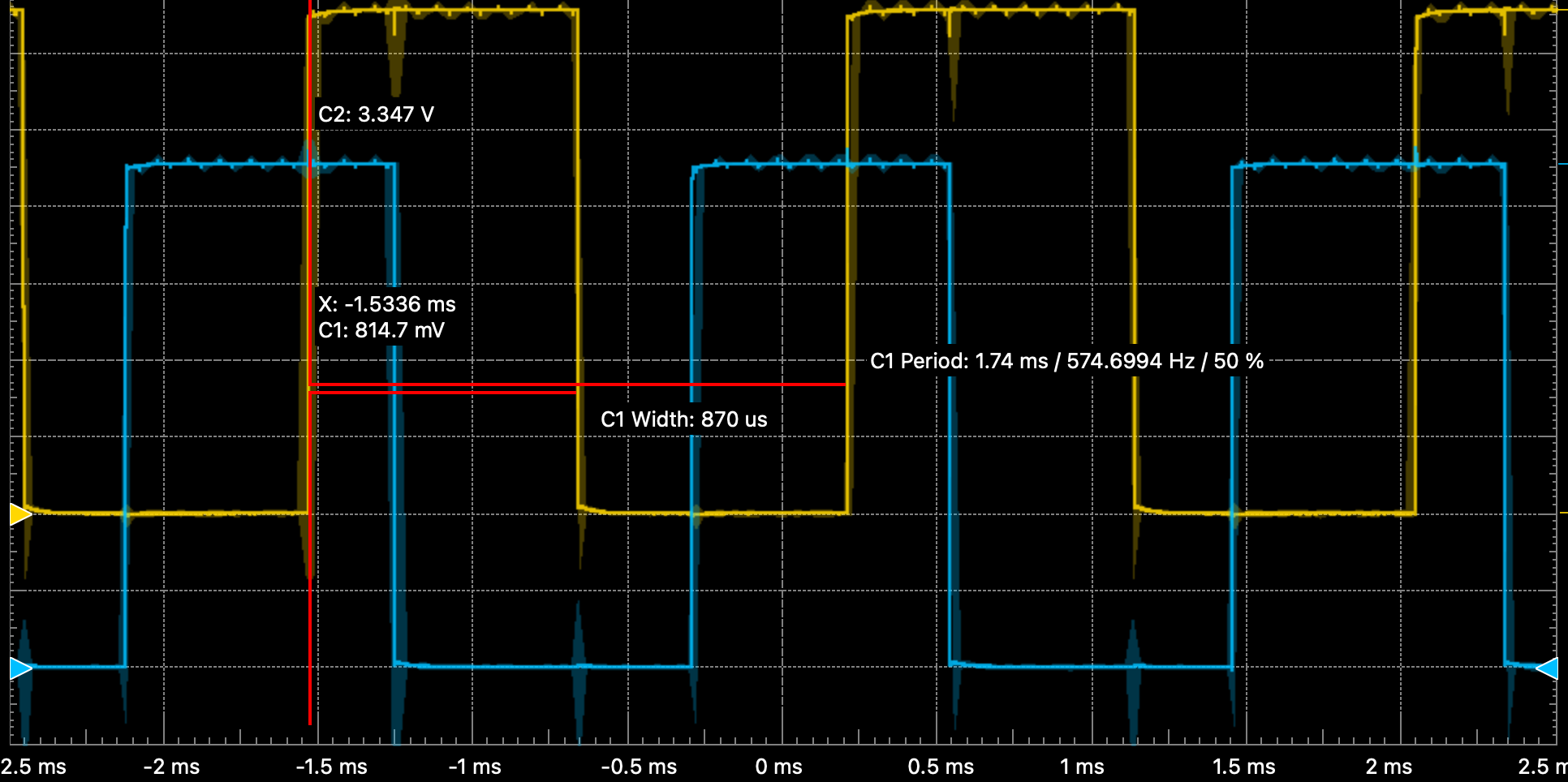

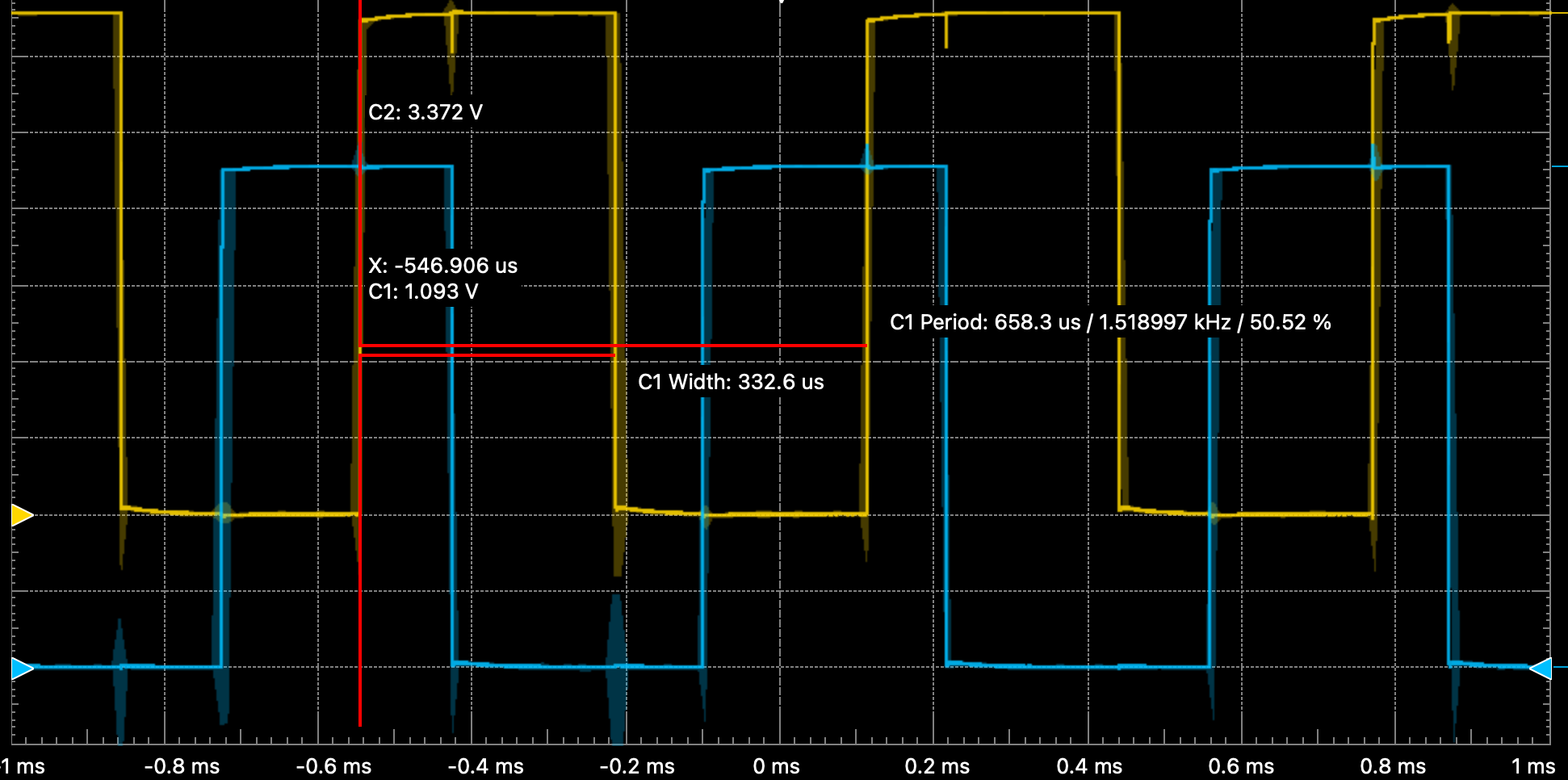

Fig. 27 Quadrature encoder signals for motor duty = 40%.#

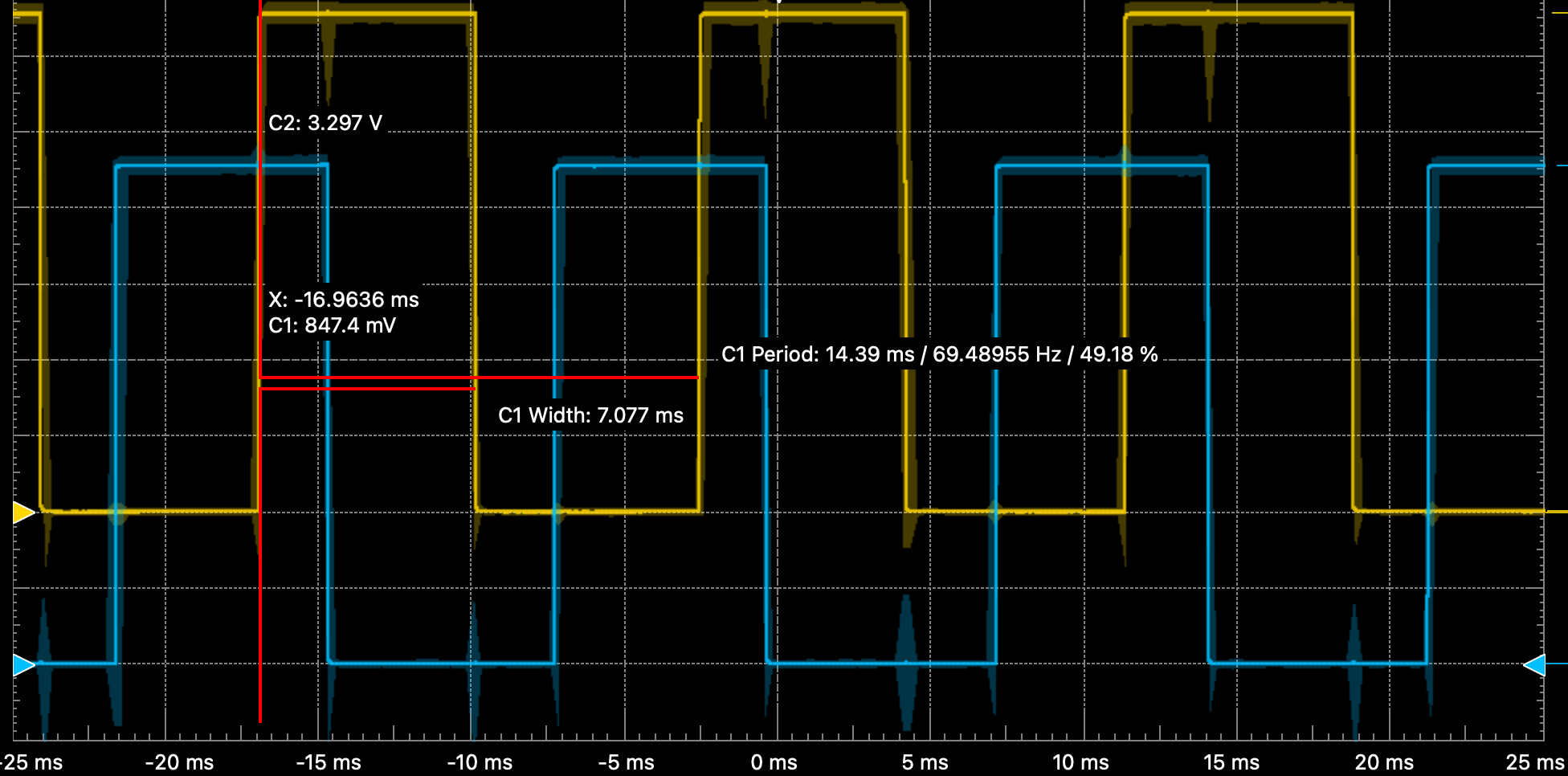

The the output period as a function of duty cycles is

Duty [%] |

Period [ms] |

|---|---|

10 |

14.4 |

40 |

1.74 |

100 |

0.68 |

Fig. 28 Encoder output for duty = 10%.#

Fig. 29 Encoder output for duty = 100%.#

At low rotation speeds, the resolution of quadrature encoders is poor. It can possible be improved by measuring the pulse width or period.

Use the code below to estimate the number of counts for a full turn of the wheel. Start the measurement, then carefully turn the wheel by hand. The value depends on the encoder and motor gear ratio. For my motors it is about 1800 counts per revolution. With the 8cm wheel diameter, this amounts to 25cm displacement or 0.14mm/count.

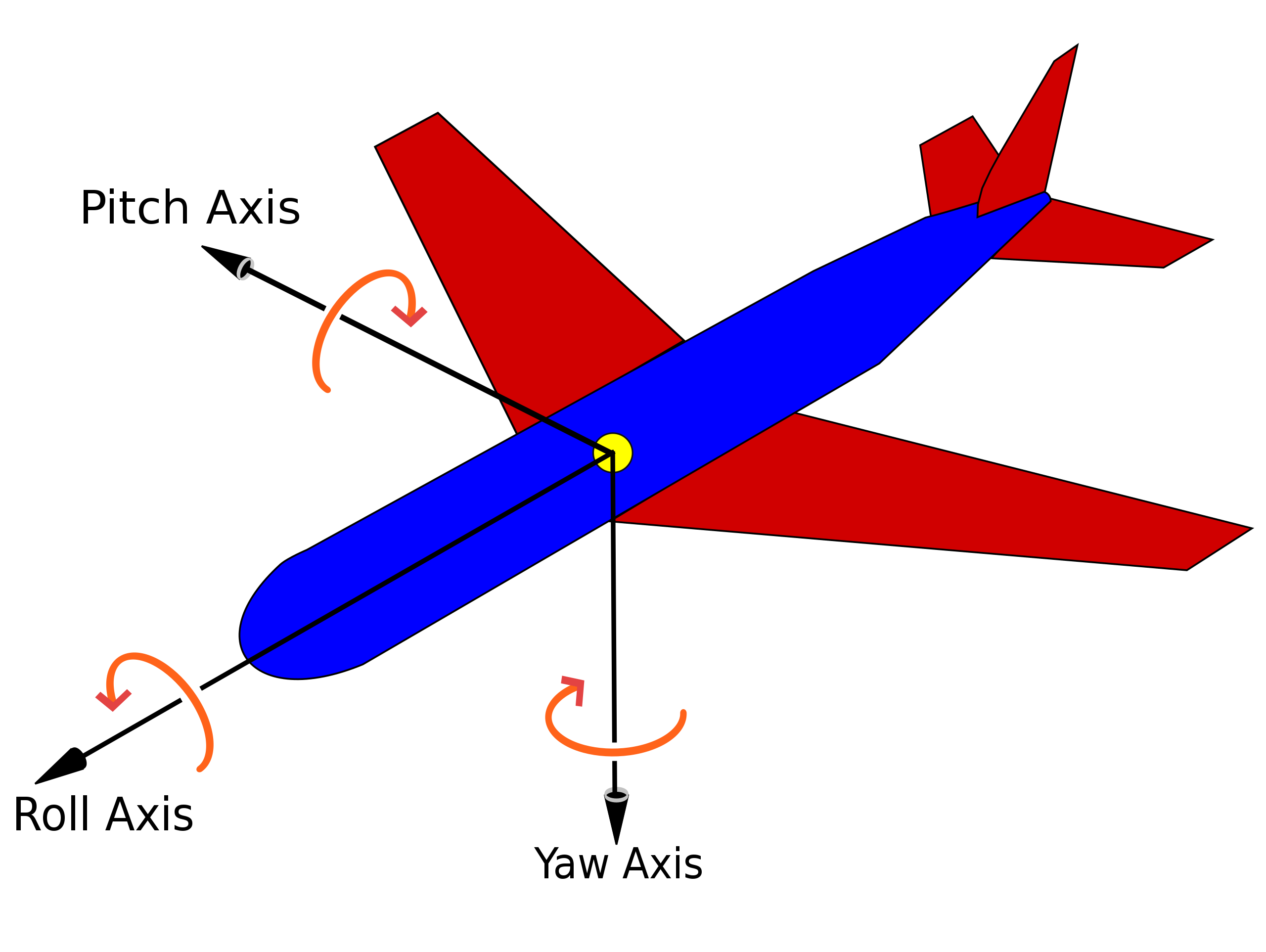

IMU#

To balance on two wheels, the robot needs to know about the direction of gravity. Specifically, we want to know the pitch angle in the figure below.

Fig. 30 Pitch, roll, and heading.#

Accelerometers and gyroscopes are perfect for this task. We will look at two solutions - one using a BNO055 IMU with on-board motion processor that directly outputs quaternions from which gravity can be calculated.

The other option uses a complementary filter to extract gravity from raw accelerometer and gyroscope output.

Below is the code using quaternions and the output from flipping the robot over.

from bno055 import BNO055, NDOF_FMC_OFF_MODE, QUAT_DATA

from machine import I2C

from time import sleep_ms

import math

RAD2DEG = 180/math.pi

# init

i2c = I2C(1, freq=400_000)

imu = BNO055(i2c, crystal=True, transpose=(2, 0, 1), sign=(0, 0, 1))

imu.mode(NDOF_FMC_OFF_MODE)

sleep_ms(800)

# read sensor and compute pitch angle

for i in range(10):

imu.iget(QUAT_DATA)

w = imu.w/(1<<14)

x = imu.x/(1<<14)

y = imu.y/(1<<14)

z = imu.z/(1<<14)

sinp = 2 * (w * y - z * x)

if abs(sinp) >= 1:

# use 90 degrees if out of range

pitch = math.copysign(math.pi / 2, sinp)

else:

pitch = math.asin(sinp)

pitch *= RAD2DEG

print(f"{pitch:8.2f}")

sleep_ms(500)

-88.01

-88.01

-87.82

-54.62

-46.12

-29.56

3.47

42.27

61.86

83.53

A little bit optimized:

from bno055 import BNO055, NDOF_FMC_OFF_MODE, QUAT_DATA

from machine import I2C

from time import sleep_ms

import math

_RAD2DEG = 180/math.pi

_90DEG = 0.5 * math.pi

_QUAT_SCALE = 1/(2<<26)

# init

i2c = I2C(1, freq=400_000)

imu = BNO055(i2c, crystal=True, transpose=(2, 0, 1), sign=(0, 0, 1))

imu.mode(NDOF_FMC_OFF_MODE)

sleep_ms(800)

# read sensor and compute pitch angle

for i in range(10):

imu.iget(QUAT_DATA)

sinp = _QUAT_SCALE * (imu.w * imu.y - imu.z * imu.x)

if abs(sinp) >= 1:

# use 90 degrees if out of range

pitch = math.copysign(_90DEG, sinp)

else:

pitch = math.asin(sinp)

pitch *= _RAD2DEG

print(f"{pitch:8.2f}")

sleep_ms(500)

-88.19

-88.15

-42.03

5.38

52.51

75.75

42.02

23.82

46.48

76.74

Complementary Filter#

The code below reports the computation time (including reading the sensor) and orientation from:

accelerometers only

gyroscope only

complementary filter combining accelerometer and gyroscope data

Euler angle computed by BNO055

The third option is robust and ideal for low-cost inertial sensors without on-board processing.

# rotate about short side of chip

import time, math, gc

from machine import I2C as I2C

from pyb import Pin

from bno055 import BNO055

tau = 0.2

Ts = 0.02

ALPHA = tau / (tau+Ts)

RAD_TO_DEG = 180/math.pi

i2c = I2C(1, freq=400_000)

imu = BNO055(i2c)

time.sleep(1)

a_off = 0

g_phi = -90

c_phi = 0

t_last = time.ticks_us()

dt = 0

print("{:>8s} {:>6s} {:>6} {:>6} {:>6}".format("dt [us]", "xcell", "gyro", "comp", "bno055"))

for i in range(1000):

# xcell

ax, ay, az = imu.accel()

a_phi = math.atan2(ay, az)*RAD_TO_DEG - a_off

if i == 0: a_off = a_phi+90

# gyro

rx, ry, rz = imu.gyro()

g_phi += rx * Ts * 0.5 # why 0.5?

# complementary

c_phi = ALPHA * (c_phi + rx * Ts) + (1-ALPHA) * a_phi

# euler

_, _, e_phi = imu.euler()

if i % 50 == 0:

print("{:8d} {:6.0f} {:6.0f} {:6.0f} {:6.0f}".format(int(dt), a_phi, g_phi, c_phi, -e_phi-90))

# clean slate

gc.collect()

# sleep off extra time

t_new = time.ticks_us()

dt = time.ticks_diff(t_new, t_last)

t_last = t_new

time.sleep(Ts-dt*1e-6)

dt [us] xcell gyro comp bno055

0 -0 -90 -0 -91

17999 -90 -90 -89 -91

10447 -90 -90 -90 -91

5354 -113 -111 -117 -114

7995 -132 -131 -137 -134

5399 -157 -153 -161 -158

2593 -173 -168 -177 -176

11001 -197 -187 -199 -196

9994 -217 -206 -220 -216

10603 -234 -221 -236 -233

15108 -243 -231 -245 -244

11001 -256 -242 -258 -256

8185 84 -256 -123 88

3003 90 -256 84 88

8608 90 -256 90 88

7747 90 -256 90 88

5926 90 -256 90 88

4437 90 -256 90 88

8183 90 -256 90 88

10926 90 -256 90 88